1. Overview of the Power and Thermal Analyzer

2. Estimating Power Consumption with the Power and Thermal Analyzer

3. Power and Thermal Analyzer (PTA) Graphical User Interface

4. Power and Thermal Analyzer Resource Types

5. Command Line Options and Scripting

6. Factors Affecting the Accuracy of the Power and Thermal Analyzer

7. Document Revision History for the Power and Thermal Analyzer User Guide

A. Measuring Static Power

B. Tcl Command Reference

3.1. PTA - Device Selector Dialog Box

3.2. PTA - Primary GUI Components

3.3. PTA - Hierarchical Design Editor

3.4. PTA - Using Design Hierarchies in the Power and Thermal Analyzer

3.5. PTA - Entering Hierarchy Information Into the PTA

3.6. PTA - Current Drawn per Supply Tab

3.7. PTA - Temperature and Cooling Tab

3.8. PTA - Resource Utilization Panel

3.9. PTA - Register Dynamic Power in Agilex Devices

3.10. PTA - Input Fields

3.11. PTA - Data Entry Error Messages

3.12. PTA - Search Features

3.13. PTA - Filtered Searches

3.14. PTA - Using the Tcl Console to Perform Searches

4.1. PTA - Power Summary

4.2. PTA - Root Entry

4.3. PTA - Instance

4.4. PTA - Logic Resource Type

4.5. PTA - RAM Resource Type

4.6. PTA - DSP Resource Type

4.7. PTA - Clock Resource Type

4.8. PTA - PLL Resource Type

4.9. PTA - I/O Resource Type

4.10. PTA - Transceiver Resource Type

4.11. PTA - Crypto Resource Type

4.12. PTA - NOC Resource Type

4.13. PTA - HBM Resource Type

B.1. add

B.2. copy

B.3. delete

B.4. edit

B.5. export_design_file

B.6. find_instances

B.7. get_available_ips

B.8. get_available_resource_types

B.9. get_available_values

B.10. get_first_error

B.11. get_properties

B.12. get_report

B.13. get_report_names

B.14. get_results

B.15. get_value

B.16. import_design_file

B.17. move

B.18. open_design_file

B.19. pta::get_active_design

B.20. pta::get_defaults

B.21. pta::get_designs

B.22. pta::locate

B.23. pta::set_active_design

B.24. pta::set_family

B.25. recalculate_power

B.26. redo

B.27. save

B.28. set_device

B.29. set_view

B.30. undo

1.2. PTA Power Model Status

The Power and Thermal Analyzer (PTA) uses a device power model to calculate estimated power consumption and thermal assessments. Depending on the maturity of the device, the power models in the current version of the PTA may be in advance, preliminary, or final status. The status of the power models relate to the accuracy of the estimated results.

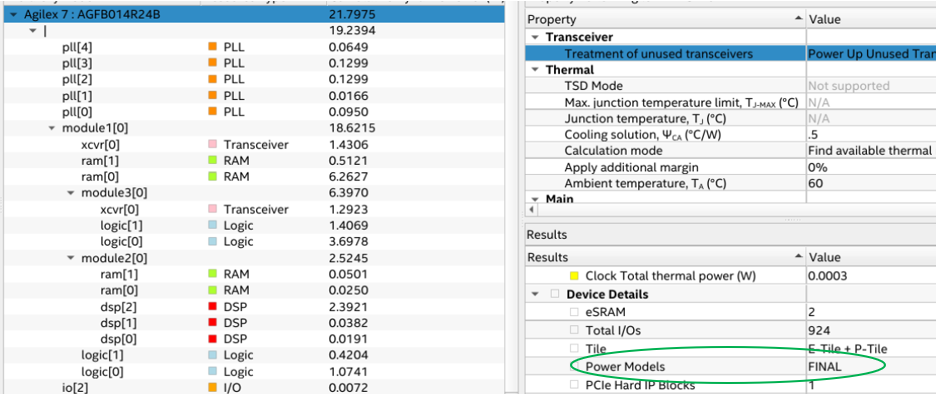

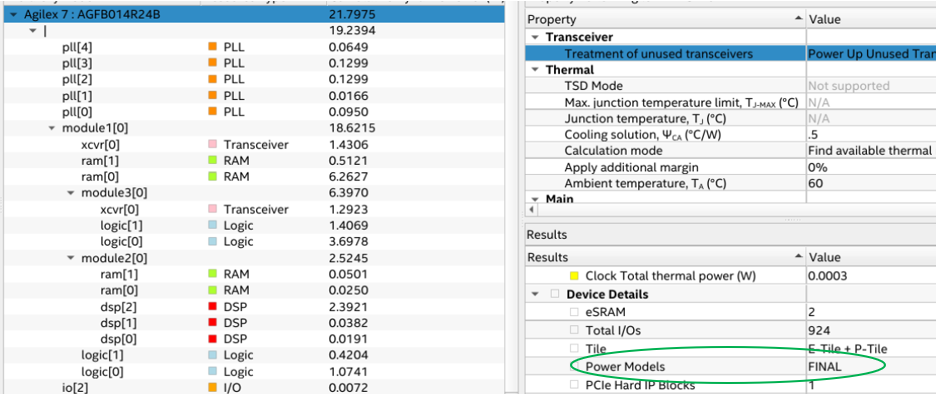

Model status for the currently selected part can be found in the results pane by selecting the part entry in the Hierarchical Design Editor:

Figure 2. Power Model Status in Results Pane

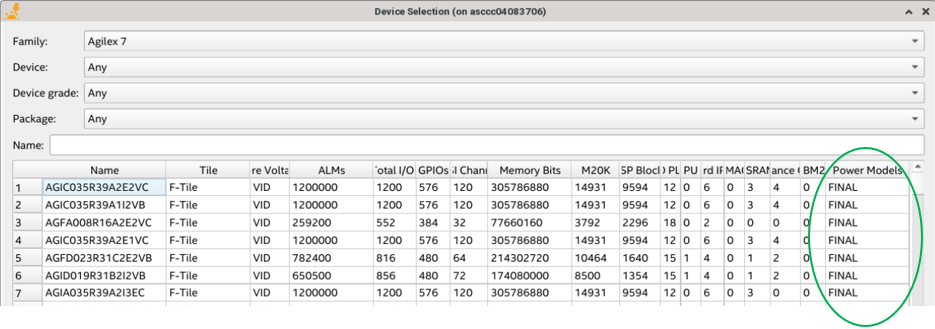

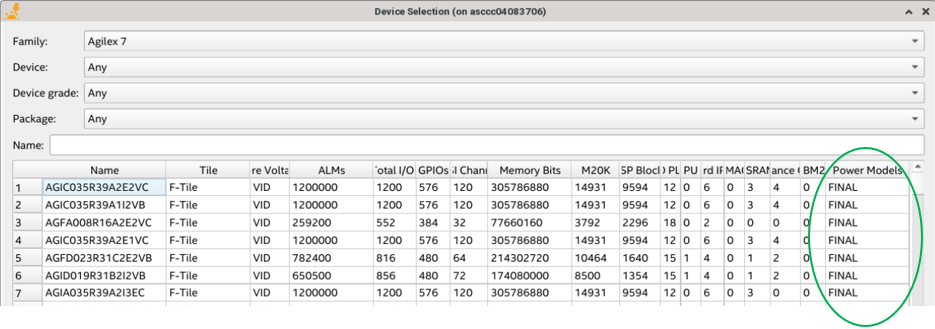

Model status for each OPN is also displayed in the Device Selection dialog box:

Figure 3. Power Model Status for Each OPN in Device Selection Dialog Box

The possible power model statuses are as follows:

- Advance power models— based on simulation results, process model projections, and design targets. Advance power models may change over time.

- Preliminary power models—include post-layout simulation results, process data, and initial silicon correlation results. Preliminary power models may change over time.

- Final power models—correlate to production devices with thousands of designs, and are not expected to change.

The accuracy of the power model is determined on a per-power-rail basis for the PTA.

- For most Stratix® 10 designs, the Power and Thermal Analyzer has the following accuracy, assuming final power models: within 15% of silicon for the majority of power rails with higher power, assuming accurate inputs and toggle rates.

- For most Agilex™ designs, the PTA has the following accuracy, assuming final power models: within 10% of silicon for all power rails, assuming accurate inputs and toggle rates.

For more information about power model accuracy in the Quartus® Prime Power Analyzer, refer to the Quartus® Prime Pro Edition User Guide: Power Analysis and Optimization.