AN 672: Transceiver Link Design Guidelines for High-Gbps Data Rate Transmission

1.1.3. Fiberglass Weave

PCB boards are constructed of strands of fiberglass yarn woven into bundles with epoxy resin to form the fiberglass sheets that make up the core and prepreg laminates.

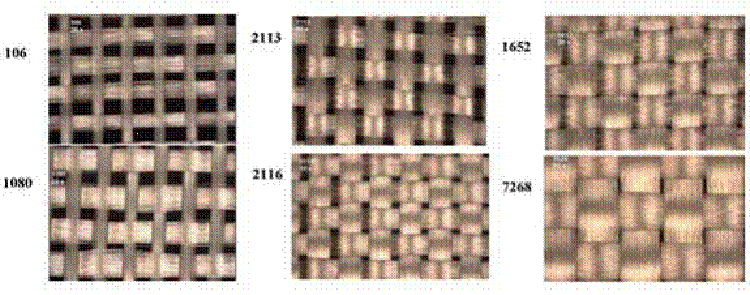

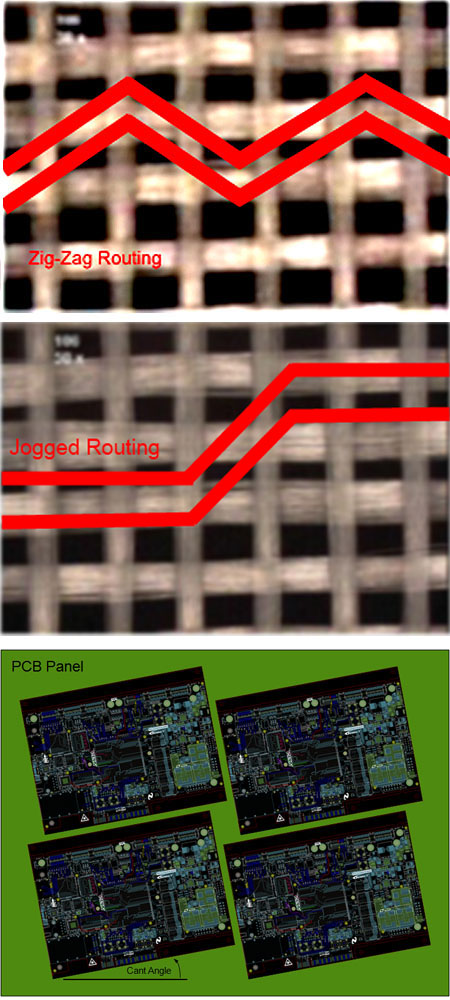

Since the dielectric constant of the fiber bundles and epoxy resin differ, the density of the fiber weaves affects the uniformity of the dielectric constant of the laminate. Sparsely woven cores and prepregs have less uniform dielectric constant and can result in impedance and signal velocity variations along the trace route. For example, consider a differential pair trace routed over 7268 style fiberglass vs. the same pair routed over 106 style fiberglass. The 7268 glass provides a more uniform dielectric constant since the copper traces always reside over the glass. However, traces routed over 106 style glass can result in having a differential pair with one leg routed over glass while the other alternates between glass and resin. The main concern is each leg having different impedances and skew in the differential signal. Although there are routing techniques such as using zig-zag, jogged routing, and placing the complete board design at a slight cant on the PCB panel to average out the on-weave/off-weave problem and mitigate the signal velocity variation, these techniques trade off valuable board real estate while not fully resolving the impedance variation and reflection problem. Additionally, these compensation techniques increases the trace lengths, causing additional loss.

As a result, for very high-Gbps data rates, select higher density fiberglass laminates for the high speed routing layers while relegating sparsely dense fiberglass to lower speed and power layers to offset the PCB cost.