Simplify IoT and improve manufacturing operations with a reliable and secure Industrial IoT platform

“Litmus Automation* helps industrial customers connect to their diverse assets at the edge quickly and easily, allowing them to analyze operational data for successful IoT deployment.”

Vatsal Shah, cofounder and CEO,

Litmus Automation*

Executive summary

The merger of OT and IT promises to bring new levels of connected intelligence and efficiency to today’s manufacturing operations. However, obstacles ranging from incompatible systems to increased security risks are impeding progress in the Industrial Internet of Things (IoT). Together, Litmus Automation and Intel are bridging the gap for industrial legacy devices, systems, and infrastructure by connecting systems, collecting data, and performing analytics at both the edge and the cloud to increase efficiency and productivity, improve quality, and lower costs.

Challenges

The vast mix of proprietary systems, sensors, and devices, often with unique protocols and diverse structured and unstructured data formats, poses a considerable obstacle to industrial IoT growth—limiting holistic visibility into industrial operations, automation, and optimization.

Device and data security is a key concern as previously disparate systems were not meant to be connected to the internet and cloud. As a result, many manufacturers are keeping systems and data behind a centralized firewall with manual maintenance, leading to a negative impact on timeliness, flexibility, and costs.

Applications are often installed, managed, and patched individually, a laborintensive process that prohibits agility. Unfiltered data is sent directly to the cloud, making for high transmission and storage costs without the value of actionable, near-real-time insight. In addition, the ramp-up to IoT can be both time-consuming and risky, with long and costly development cycles and results that are not future proofed for the rapidly changing technology market.

Solution

Litmus Automation solutions powered by Intel® architecture bring manufacturers the advantages of cutting-edge IoT projects—from artificial intelligence to machine learning. The solution gives industry the data-driven insight to inform a wide range of essential manufacturing processes, including predictive maintenance; monitoring of production lines, networks, and supply chains; capacity and energy utilization; load balancing; demand forecasting; and more.

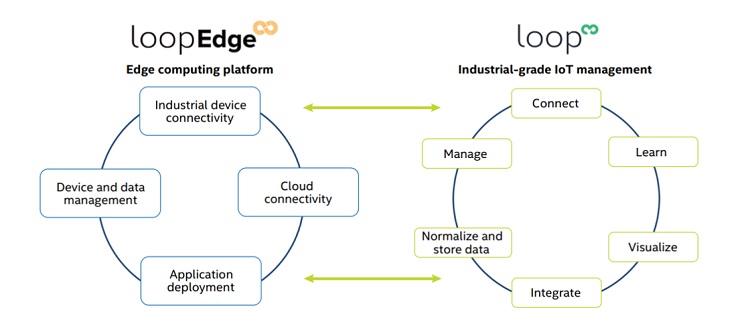

Litmus Automation’s Loop* and LoopEdge* offer an end-to-end, secure, scalable IoT platform powered by Intel architecture, enabling clients to connect any number of devices to the internet, manage those devices, and integrate them with any application.

Modern industry requires both actionable insight at the edge, along with deeper analytics in the cloud

Industrial sector benefits

Increase operational visibility

- Track critical assets in near-real-time using RFID, shop floor sensors, and warehouse management systems

- Increase data visibility with near-real-time visualization

- Remotely monitor assets and infrastructure

- Optimize inventory management

Decrease risk

- Reduce the scope and impact of adverse events

- Help eliminate the instantaneous cost of failure

- Optimize maintenance schedules on older machines

Increase control

- Measure near-real-time physical inventory of assets

- Improve quality and quality control by maintaining full traceability of the digital thread from raw material to product

- Increase analytics reliability

Save costs

- Save time and money in the production process

- Increase asset utilization

- Decrease infrastructure and energy costs

- Decrease support and maintenance labor and costs

Increase productivity

- Improve inventory and manufacturing performance

- Utilize predictive maintenance

- Decrease downtime

Help secure data and devices

- Prevent assets from leaving the premises

- Keep designated assets out of unauthorized areas

Create new revenue streams

- Align strategy and business models

- Enhance customer support

Together, LoopEdge* and Loop* powered by Intel® architecture enable industrial manufacturers to inform and optimize operations with near-real-time data from the edge

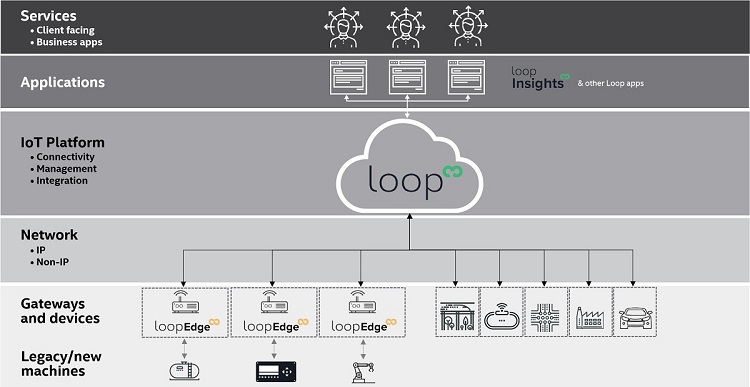

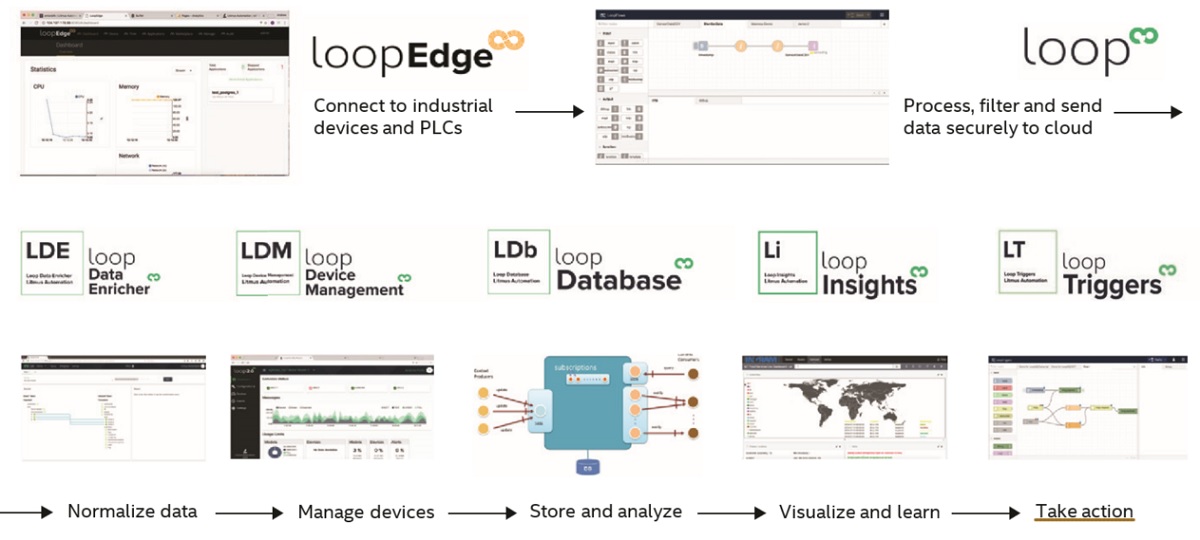

LoopEdge brings edge intelligence to production lines by collecting, storing, and analyzing data at the edge in conjunction with an Intel architecture-based gateway. LoopEdge provides the ability to collect the data from any type of legacy or modern device, no matter when it was deployed, with standardized device and data management, scalable application deployment, and enhanced security. Capabilities include mass application deployment and management, edge analytics and alerts, anomaly detection, machine learning, and, via Loop, failure prediction and key performance indicator (KPI) visualization.

Loop is designed to connect any device to any application. Loop scales efficiently, accelerates deployment, and is built to be cost-effective for manufacturing installations. Loop manages IoT assets via an Intel architecture-based server, collecting and managing data from any device and providing data warehousing and batch analytics. It offers deep integration with other business applications and supports complex IoT deployments. Loop capabilities include data integration, ingestion, storage, normalization, and device management combined with rules-based security. The solution is device-, protocol-, and application-agnostic, with one-click integration for applications.

Connect and manage any device. Integrate into any application.

LoopEdge*

- Connect industrial and legacy systems

- Increase security

- Normalize data

- Enable edge data analysis and local processin

Loop*

- Manage devices

- Deploy standardized IoT solutions

- Manage product lifecycles

- Support complex deployments

LoopInsights*

- Visualize and build applications

- Integrate data and access to improve decision-making

- Apply rules and alert engines

- Accelerate analytics

Industrial use cases

Machine health and anomaly detection

Litmus Automation’s industrial manufacturing IoT solutions manage communications and data processing for embedded legacy equipment on the factory floor. Production line anomalies from old machine systems can require longterm and costly maintenance. Loop and LoopEdge enable predictive maintenance, helping to eliminate the cost of failure on old machine systems. Machine learning is utilized to identify and predict production line anomalies

Predictive maintenance

LoopEdge collects standardizes, isolates, secures, and pushes device data to the Loop data center platform, enabling immediate and long-term predictive maintenance of potentially failing systems.

Near-real-time production monitoring

Together, Loop and LoopEdge enable production line monitoring via the convergence of OT and IT.

Asset and material tracking

LoopEdge and Loop facilitate integrated asset management to help ensure logistics optimization through easy location and monitoring of assets and materials. The solution monitors internal and external operating conditions, systems, and events, as well as the traditional parameters of quality, inventory, maintenance, and quantity.

Advancing edge and cloud intelligence

Intel and its ecosystem help businesses use the IoT to solve long-standing industry-specific challenges. Quickly develop IoT solutions that connect things, collect data, and derive insights with Intel’s portfolio of open and scalable solutions so you can reduce costs, improve productivity, and increase revenue.

Intel® technologies support the rigorous requirements for programmable logic controllers (PLCs), industrial PCs (IPCs), human machine interfaces (HMIs), robotics, machine vision, and many other industrial applications.

The Loop* platform running with Intel® architecture connects industrial systems to a myriad of leading-edge manufacturing use cases

How it works in brief

The Loop management dashboard works with RESTful APIs to support both legacy and modern industrial infrastructure. The Loop ecosystem supports common coding languages including Java*, Javascript*, C/C++/C#, Python*, Lua*, .NET Micro*, and Objective-C*.

LoopEdge* offers connectivity between manufacturing devices and systems via an Intel® architecture-based gateway

Technical features are designed to simplify IIoT through flexible Litmus Automation middleware and the high performance, future-proof scalability, and reliability of Intel architecture.

LoopEdge* offers connectivity between manufacturing devices and systems via an Intel® architecture-based gateway

Advance VPN and management

- Device management and remote access

- Data standardization and normalization

- Event processing

- IoT security and compliances

Loop scalability and high-availability

- Handles large numbers of connected clients

- Supports more than 500,000 connected devices per cluster

- Scales as business evolves

- Supports multiple data centers

- Increases reliability and handle failover

- State-of-the-art orchestration and load balancing

Loop bootstrap, registration, and mass deployment

- Separate user and device management systems

- Deploy, enable, disable, and upgrade remotely

- Measure performance, bandwidth, and status in near-real-time

- Group with filters

- Support for custom APIs

- Utilize existing management tools

LoopEdge local data storage and processing

- Stores latest readings for apps or cloud connector to consume

- Stores in native JSON*

- One database for all device data and RESTful API access

- Encryption, if required

- Swagger* APIs, configuration access, and persistent long-term storage

LoopEdge device connectivity based on industrial drivers

- Many drivers included

- Seamless management

- Public and private application marketplaces

- UI– and flow–based configurations with no coding required

- Native cloud connectivity

Litmus Automation’s product portfolio helps ensure comprehensive insight into industrial data

Enhance security for data at flight and at rest

Litmus Automation solutions reduce risk with enforced privacy controls on each device and connection. Advanced SSL/TSL standards, AES encryption, and low latency combine to safeguard embedded devices.

For added protection, Loop uses transport-layer security with granular controls and a publish/subscribe architecture that does not store a single byte of client data. Data is authenticated and authorized in flight and at rest.

The foundation for IoT

Litmus Automation solutions provide one example of how

Intel works closely with the IoT ecosystem to help enable smart solutions based on standardized, scalable, reliable Intel® architecture and software. These solutions range from sensors and gateways to server and cloud technologies to data analytics algorithms and applications. Intel provides essential end-toend capabilities—performance, manageability, connectivity, analytics, and advanced security—to help accelerate innovation and increase revenue for enterprises, service providers, and industry.

Conclusion

With Litmus Automation software running on Intel architecture, manufacturers can access and analyze essential data across both legacy and modern infrastructure. The resulting insight can transform operations—from efficiency and predictive maintenance to new business models—and bring the competitive benefits of IoT.

About Litmus Automation*

Litmus Automation is an edge and cloud Industrial IoT provider dedicated to providing clients with a secure, scalable, and efficient platform to deploy IoT strategies and solutions. The LoopEdge and Loop platforms are production-ready and tested with Fortune 500 companies.

Litmus Automation was named May 2018 Cool Vendor for IoT Platforms by Gartner, and a leading vendor in MachNation’s 2018 IoT Edge Scorecard. Litmus Automation

Learn more

For more information about Litmus Automation*, please visit Litmus Automation or contact us at info@litusautomation.com.

For more information about Intel® IoT Technology and the Intel® IoT Solutions Alliance, please visit Intel Internet of Things (IoT).