In many manufacturing plants today, monitoring is a highly manual process. FOURDOTONE Teknoloji analyzes data from sensors to enable manufacturers to respond immediately to problems, and predict when machines are likely to fail.

Executive Summary

Downtime can be expensive, and in a tightly coupled manufacturing line a problem with one machine can have an impact on the entire factory. For many factories, avoiding downtime is a matter of luck rather than science: machine inspections are infrequent, and only capture what’s visible to the eye.

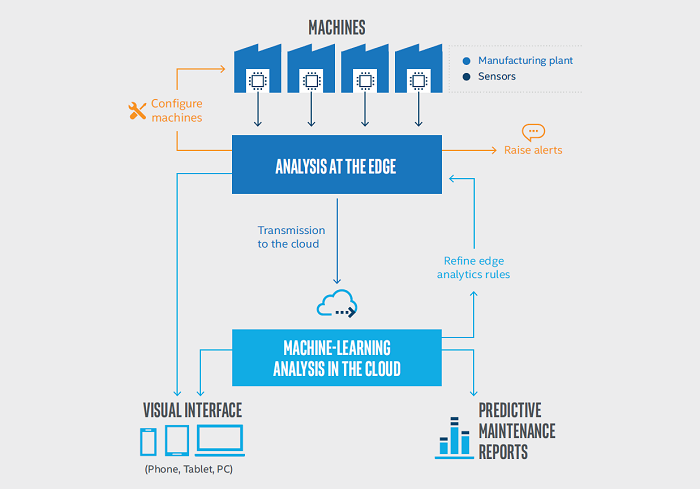

4.1 Industrial Internet of Things Platform (4.1 IIoTP) from FOURDOTONE Teknoloji enables manufacturers to be more responsive and proactive in their maintenance, so they can aim to minimize downtime. Data is gathered from the machines and analyzed in the factory, enabling an immediate response to emergencies or imminent problems. In the cloud, machine-learning algorithms are used to analyze the combined data from all of the machines, so that future maintenance requirements can be predicted. That enables the manufacturer to plan its maintenance to avoid downtime, and optimize its maintenance costs.

The technology provides a foundation for continuous improvement, and enables manufacturers to cut the risk of unplanned downtime.

FOURDOTONE Teknoloji was founded in 2014 in Turkey and specializes in Industry 4.0 projects. The company works on hardware independent projects including condition monitoring, big data process optimization, predictive maintenance and the digital factory. The company serves enterprises in Turkey, Central and Eastern Europe, and the Middle East.

Business Challenge: Avoiding Downtime in Industry

For manufacturing plants, downtime can have a huge impact on the business. A fault in a single machine could halt the production line. For plants that operate around the clock, that time can never be recovered. An unexpected drop in output can result in the business disappointing customers who are depending on its deliveries. It can have a direct impact on revenue, with orders lost and product unavailable to sell.

In many manufacturing businesses, unplanned downtime is hard to avoid. Maintenance remains reactive. Companies are unable to monitor and analyze their plant in real time, so they don’t know that there is anything wrong until a machine grinds to a halt. Without any reliable data on the past, they are unable to make any predictions on when machines are likely to fail.

Efforts to manage the plant are labor intensive, and prone to missing important signals. People might go from machine to machine, checking with the naked eye for any anomalies and collecting data with clipboards. The manual observation and the often infrequent checks make it difficult to detect potential problems without luck. If a check isn’t carried out in the right place at the right time, it’s not going to find a problem that might already be affecting performance, and might ultimately result in an outage.

The Machinery Monitoring Challenge

One organization facing these challenges is the Scattolini Turkey plant. It manufactures floats and tippers for commercial vehicles. The company is headquartered in Italy, and produces more than 200 types of equipment from its plant in Valeggio sul Mincio, and its seven other sites worldwide. Its plant in Turkey manufactures parts for vans.

Uptime is critical for its operations and its profitability. The company wants to transform from reactive maintenance to predictive maintenance: ensuring it can intervene before there is any downtime. A single day’s outage can cost as much as 35,000 EUR, including the cost of repair.

Its existing regime is based on manual inspection with monthly vibration measurements and reactive maintenance. The company needs a way to:

- Gather data from its plant of over 30 machines, without requiring a visit to them. The machines include cranes, fans, and pumps;

- Monitor the levels of liquid chemical ingredient pools;

- Identify any problems as and when they occur, enabling an immediate response to minimize downtime;

- Model likely future failures, so the maintenance team can carry out any repairs or replacements before there is an outage.

Solution Value: Enabling Predictive Maintenance

4.1 IIoTP gathers data wirelessly from the shop floor and analyzes it. In the case of the Scattolini Turkey plant, the data gathered includes axial vibration, surface temperature of motors, pressure of hydraulic and pneumatic systems, liquid levels in tanks and pools, and the status of the main energy line. The solution enables the plant to have access to more information, and on a more timely basis, than was previously possible. As a result, the company has a clearer insight into the status of its plant and its maintenance requirements. The data is analyzed in two stages: first, if there is an anomaly in the incoming data, an alert is raised immediately. An SMS message or email is sent to the predefined user group. In the event that there is no response, or there is a safety issue, the software can be configured to automatically shut down the machine.

The second stage of analysis takes place in the cloud. Combining the data from all the machines, 4.1 IIoTP can predict likely future outages and maintenance requirements. This approach uses machine-learning techniques to compare what is known about past failures, with current data about the plant and its equipment. By replacing parts before a likely failure, Scattolini can avoid unplanned outage.

The team at the Scattolini Turkey plant can use a cross-platform portal on computers, phones or tablets to monitor the state of the plant in real-time.

By reducing the amount of manual monitoring and transforming the factory to become proactive with its maintenance, Scattolini estimates that it has reduced its costs for maintenance operations by 15 percent.

Solution Architecture: Predictive Maintenance

To enable predictive maintenance, 4.1 IIoTP provides a mechanism for collecting data from the shop floor, analyzing it immediately for anything requiring a prompt response, and carrying out in-depth analysis in the cloud for predictive maintenance.

The machines to be monitored are fitted with battery or DC-powered wireless industrial sensors, manufactured for precision and operation in harsh environments.

4.1 IIoTP uses Intel® IoT Gateway Technology in the Dell Edge* Gateway 5000 to collect data from the sensors. Both wired and wireless connections are supported. The rugged and fanless gateway device is based on the Intel® AtomTM processor, which provides intelligence for devices at the edge of the network. Compute power at the edge enables fast decision making which can be critical at sites such as heavy industrial plants, fast moving production lines and chemical substance storage facilities.

Supervisory control and data access (SCADA) industrial control systems generally show current data. 4.1 IIoTP adds the ability to view historical data, and to automatically detect anomalies and threshold violations at the edge. Alerts can be raised by email or SMS, and 4.1 IIoTP can also intervene directly, changing the configuration of the machine or powering it down. This capability is provided by libraries and frameworks that enable 4.1 IIoTP to control the programmable logic controllers (PLCs). Leading PLCs are supported, including those from Siemens, Omron and Mitsubishi.

Additionally, data is sent to the cloud with 256-bit encryption. 4G/GPRS mobile broadband communication technologies are used to send data to the cloud, because they are more stable than Wi-Fi in industrial environments. In the cloud, data from all the gateways can be collected in one place and analyzed with machine-learning algorithms. This analysis can be used to predict likely machine failures, and to identify other opportunities for efficiency and quality gains. New rules can be created through machine learning for the analysis at the edge, to enable continuous improvement.

Figure 1. Using machine learning and edge analysis, 4.1 IIoTP enables an immediate response to urgent issues, and an in-depth analysis in the cloud to support continuous improvement

The cloud infrastructure is built on Amazon Web Services (AWS*). Amazon Kinesis Streams* are designed to continuously capture large volumes of data, and this service is used by 4.1 IIoTP to collect the data from the monitored devices. That data is also added to Amazon Simple Storage Service* (Amazon S3*), where it serves as a data lake, bringing together data from different types of monitored devices. Amazon Elastic MapReduce* (Amazon EMR*) is used to set up Spark* clusters, and map S3 objects to the EMR file system, so that batch analyses can be performed using the data in the S3 buckets. The predictive models are run in EMR, and data can also be consumed from Kinesis streams to enable real-time analysis on sensor data. The database, API and web servers are also hosted on AWS, using Amazon Elastic Compute Cloud* (Amazon EC2*). Users can remotely monitor the platform using a visual interface, on their choice of Internet-enabled device.

Conclusion

Manufacturers can use 4.1 IIoTP together with sensors fitted to the machines, to get an insight into the current and future health of their factory equipment. Analysis at the edge enables a prompt response in the case of an emergency, power outage or technical fault. Machine-learning algorithms in the cloud can analyze all the data generated by all the machines over time to refine the rules for raising alerts, and provide insight into the optimal time to maintain or replace a machine. This intelligence enables the manufacturer to avoid unplanned downtime, reduce the labor costs associated with monitoring machines manually, and optimize the cost of parts and maintenance. In turn, this enables manufacturers to increase the reliability and predictability of their manufacturing infrastructure.

Find the solution that’s right for your organization. Contact your Intel representative or visit Industrial Home

Intel Solutions Architects are technology experts who work with the world’s largest and most successful companies to design business solutions that solve pressing business challenges. These solutions are based on real-world experience gathered from customers who have successfully tested, piloted, and/or deployed these solutions in specific business use cases. Solutions architects and technology experts for this solution brief are listed on the front cover.