This week we will talk about the prototyping phase of Vitruvian VR and we will know the Maker who has worked to build the mechanical part and the design: Michele Ghedina.

The work of Michele was fundamental to realize this ambitious project, he worked on designing and prototyping of the iron structure.

The idea of Vitruvian project was born on the occasion of the Maker Faire in Rome, in December 2017, one of the most important event in the world of innovation. It was a huge success!

Vitruvian represents for us a big hard challenge and at the same time an hyper nice occasion to work with a nice group of friends.

But, how did we realize the job?

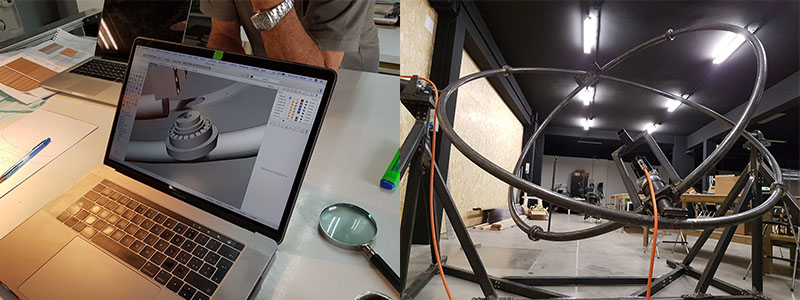

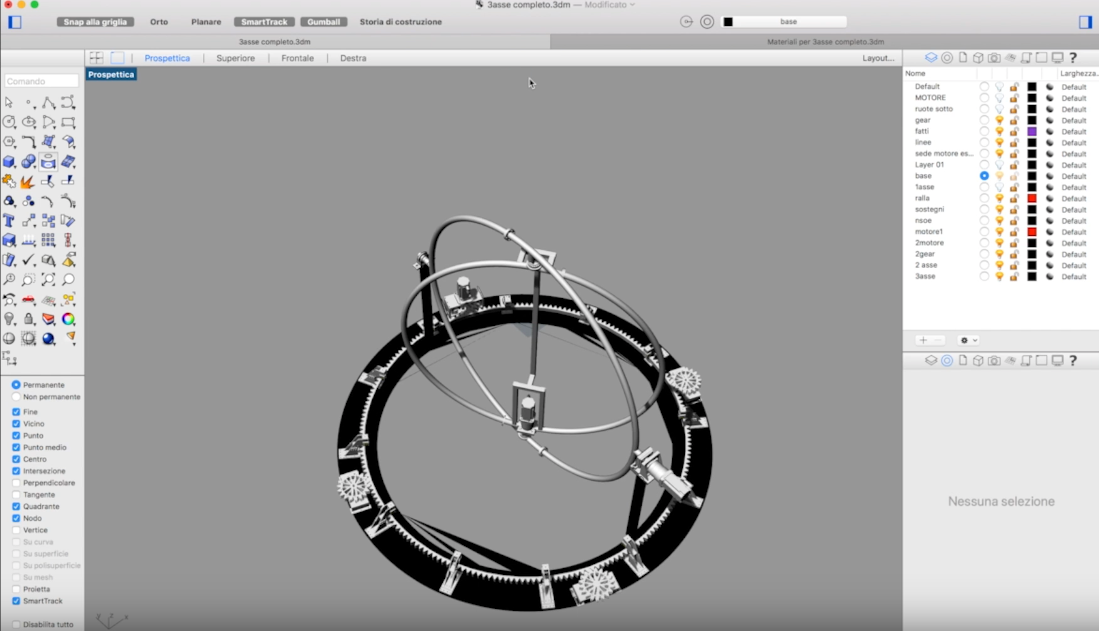

We started from the realization of the prototype design with Rhinoceros Cad software, then we simulated the operation of all the mechanical parts and gears with an electromagnetic force analysis to safely calculate the mechanical loads of the machine.

To test everything we made most of the components with iron and some of them with high precision CNC machines and 3D printing technologies.

In the second part of the video you can see the technical details of the 3D CAD realization, that allowed us to build a transportable and easy to assemble prototype.

Every metallic component is made in turn of many different parts... let's see them together!

For more information please visit Vitruvian VR website: http://www.VitruvianVr.com